Ardglen Resource Optimisation using world-first Direct Block Scheduling approach

Ardglen Resource Optimisation using world-first Direct Block Scheduling approach

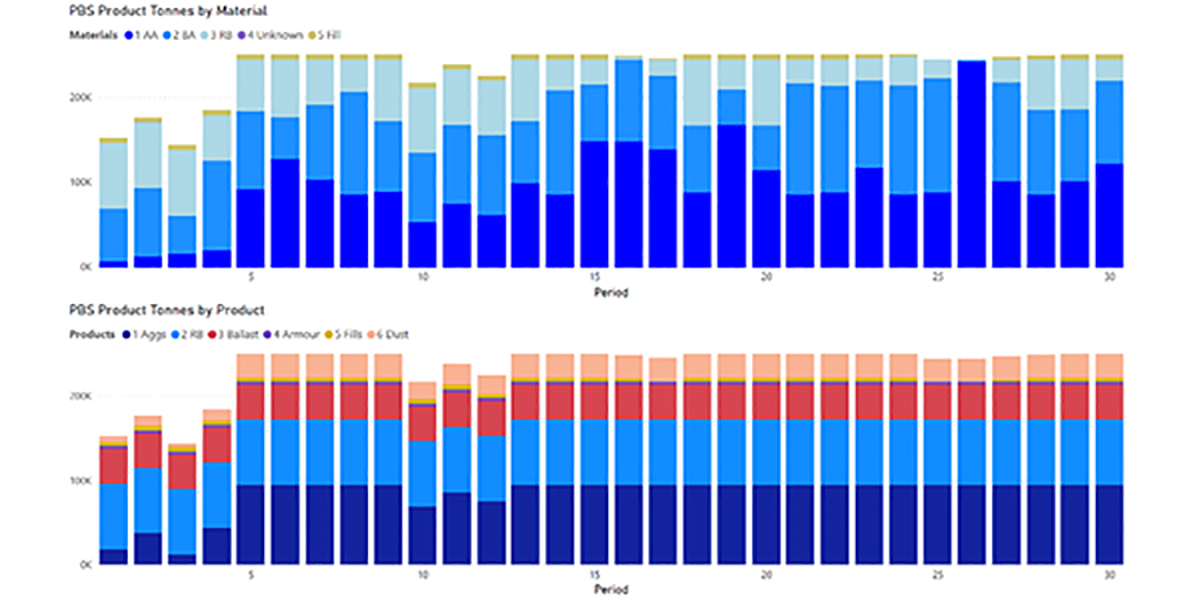

The Ardglen quarry produces a blend of road base, aggregates, and several other minor products, such as armour rock, ballast, and dust.

The quarry already had a long-term extraction plan in place based on a previous generation geological model, and manually determined extraction sequence.

Given the degree of variability of the geological materials, Eltirus suggested that the quarry use Resource Optimisation to work out the best way to stage extraction. A set of optimisation scenarios were undertaken to investigate the impact of various assumptions regarding mining intensity, product blend ratios, sales forecasts, and extraction limits.

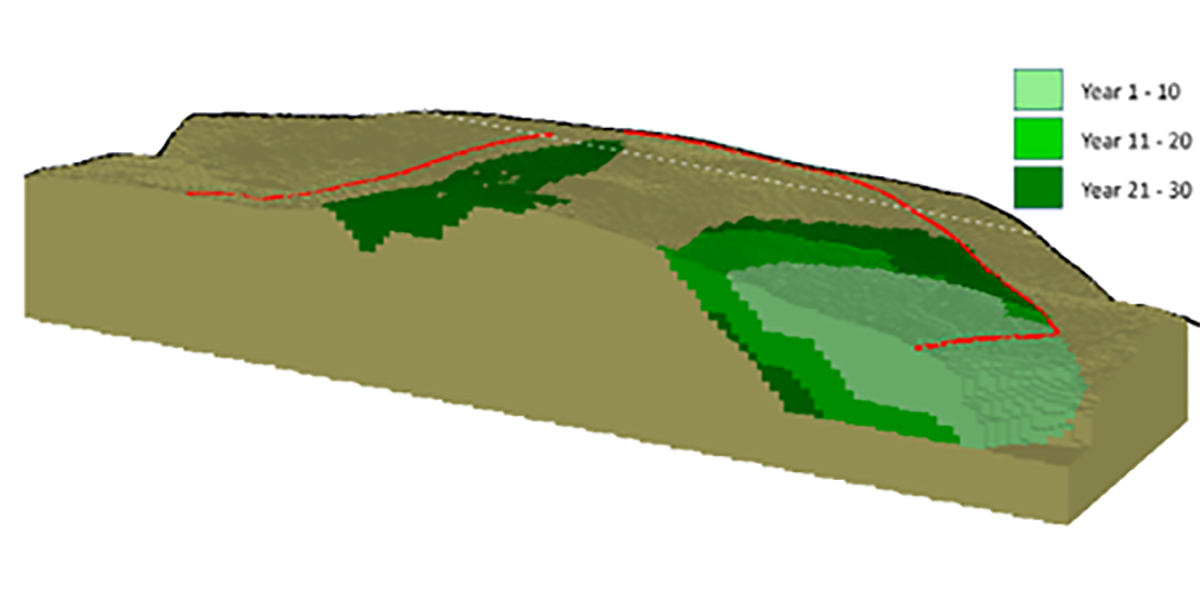

The goal was to determine not only the optimal pit shell and extraction sequence, but also to explore whether changing the assumptions significantly altered the optimal pit boundary or staging sequence over a 30-year period. A recommended optimal pit and extraction sequence was thus determined after analysing various scenarios.

To evaluate the value gained from optimisation, Eltirus explored an additional scenario where extraction was in line with the original, conceptual, and non-optimised staged extraction plan. These results were compared to the optimised case.

Results

Most of the stripping is in the first six years of the schedule. Through optimisation, this was minimised and spread across later years, resulting in a 42% improvement in NPV.

See also the article – The value of resource optimisation

For more information

Contact Steve Franklin on steve.franklin@eltirus.com or +61 474 183 939.